Buy the best types of plastic raw material at a cheap price

The raw material used in plastic products nowadays has a name list consisting of many different items

Some pdf files are available on the internet consisting of all the plastic raw material types

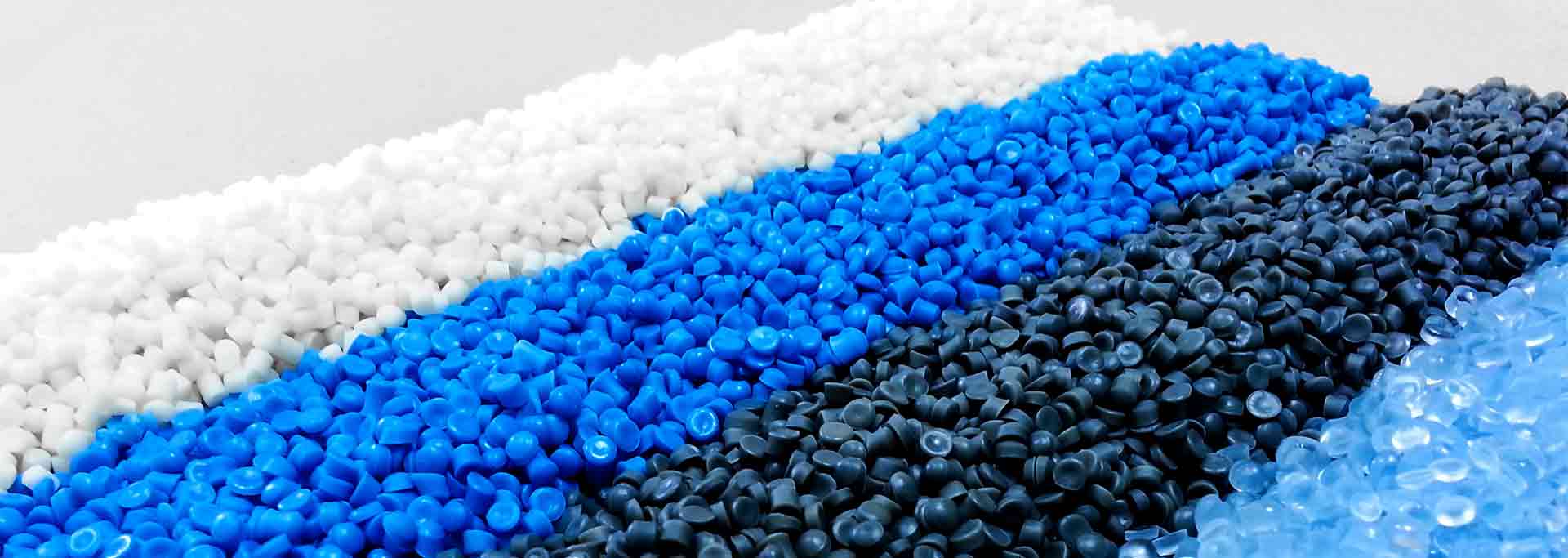

The introduction and widespread use of plastic in many typical applications that historically relied on conventional materials such as metal, glass, wood, or cotton are one of the most significant innovations of the last century

Plastic

Plastics have revolutionized various industries because they can endure environmental degradation over time, be usually safe, cost-effective, and widely available, and provide an extensive array of material properties

That can handle a variety of purposes

Here is a list of the top plastics’ raw materials that the current world cannot exist without

Polyethylene terephthalate or PET, Polyethylene or PE, Polyvinyl chloride or PVC, Polypropylene or PP, Polystyrene or PS, Polylactic Acid or PLA, Polycarbonate or PC, Acrylic or PMMA, Acetal or Polyoxymethylene (ROM), Nylon or PA, and ABS or Acrylonitrile Butadiene Styrene

In this article, we are going to explain them in short

Plastic raw material name list

The list is quite long, but in this part, we are going to have a short overview to name plastic raw material types, including PET, PE, PVC, PP, and PS

Polypropylene or PP is employed in a wide array of applications, including consumer packaging, automotive plastic components, and specific equipment such as textiles

It is transparent, has low friction, does not mix well with liquids, is readily patched, and has excellent electrical resistance like good electrical insulation

Disposable plastic

Perhaps most critically, polypropylene is versatile in a wide array of manufacturing techniques, making it one of the most commonly utilized polymers on the market

The primary advantages of polypropylene over other polymers and materials are expressed in two simple words

Innovative uses for live hinges, Simple to construct

Polystyrene or PS is hugely used under the trade name “Styrofoam” and is often used in packaging

It is also available as a natural translucent solid and is extensively used in consumer products like as soft drink caps as well as medical equipment such as Petri dishes or test tubes

A quick assessment of the critical advantages of polystyrene over other polymers and materials is its foam applications

Polyethylene terephthalate or PET (PETE) is the world’s most regularly used plastic raw material which is primarily employed as a fiber (often referred to as “polyester”) and in packaging or bottling

PET, for example, is a highly recyclable material used in water bottle

Three words or phrases explain the primary advantages of polyethylene over plastic and other plastic materials: Fibers that are frequently employed (“polyester”), Moisture block that works best, and Unbreakable

Polyethylene or PE exists in a variety of types, the most frequent of which are low density (LDPE) and high-density polyethylene (HDPE), and the properties of the material vary dependent on the sort

Low-density polyethylene (LDPE) is a polymer that is used in food bags

It has a remarkable ductileness but a weak tensile strength

HDPE is a hard plastic that is employed in harsher plastic packaging such as laundry detergents, construction applications, and trash cans

UHMW is also a robust plastic that is as strong as or stronger than steel and is applied in medical equipment such as prosthetic hip joints

Polyvinyl chloride, or PVC, is arguably most known for its home and commercial construction employment

PVC is a plastic used to insulate pipes, wires, and “vinyl” siding

In the construction sector, PVC pipe is commonly referred to as “program 40,” which refers to the pipe’s thickness relative to its length

The following are three expressions or phrases that encapsulate the primary advantages of PVC over other polymers and materials: Delicate and fragile, rigid (although various varieties of PVC are supposed to be quite flexible), and tough

The list is going on in the next following section

List of plastic raw materials

As mentioned above, the list of raw plastic materials continues in this section, including PLA, PMMA, ROM, PA, ABS, and PC

Acetal or polyoxymethylene (ROM) is a high-tensile-strength plastic with exceptional creep resistance that bridges the material performance gap between most plastics and metallic elements

It is well-known for its heat, abrasion, water, and chemical resistance

It also has a low coefficient of friction, which, when joined with its other properties, makes it appropriate for gear applications

A concise description of the critical advantages of acetal over other polymers and materials is that its coefficient of friction is low

Nylon or PA is employed in a wide variety of applications, including clothes, rubber reinforcing materials such as automotive tires, ropes or yarns, and other injection molding components for automobiles and equipment

It is widely used as a substitute for low-strength metals in applications such as vehicle engines because of its high strength (compared to other polymers), flexibility at high temperatures, and excellent chemical composition and compatibility

Two concise words that outline the primary advantages of nylon over alternative polymers and materials are high tenacity and resistance to heat

Polylactic acid, or PLA, is derived from biomass instead of petroleum, unlike the other polymers on this list

As a consequence, it decomposes significantly quicker than ordinary plastic materials

Two words or phrases that describe PLA’s significant advantages over other polymers and materials are 3D printing at home and change naturally by bacteria

Polycarbonate or PC is a translucent material with a high impact strength compared to other polymers

It is applied in greenhouses and police equipment where exceptional strength and light transmission are required

Two names or phrases that describe polycarbonate’s primary advantages over other polymers and materials are transparent and high tenacity Acrylic or PMMA is well-known for its application in optical equipment

It is exceedingly translucent, scratch resilient, and less prone to cause skin or human eye tissue injury if damaged near sensitive tissue, for example, by grinding

Two expressions or phrases that describe acrylic’s primary advantage over other polymers and materials: Transparent and resistant to scratches

Acrylonitrile butadiene styrene or ABS is not listed on this inventory, but it is a typical material used in quick prototyping

ABS is particularly resistant to harsh chemicals as well as physical shocks

It is easy to create, readily available, and has a low melting point, making it excellent for injection molding and 3D printing

Four phrases that explain ABS’s significant advantages over other polymers and materials are resistant to impact, easily accessible, simple to construct, and 3D printing materials

There are several polymers with good material properties to fulfill the needs of each application

We can help you identify the suitable plastic material for your purpose

We’ve been producing plastic prototypes for over 30 years, and we can aid you, or your organization brings your ideas to reality

Plastic raw materials list

The list is updated regularly, and we see new raw materials, including plastic, coming to the market every month

PET (often abbreviated PET), one of the most essential plastic raw materials, is an abbreviation for Polyethylene Terephthalate, which is the chemical term for polyester

PET is a clear, robust, lightweight plastic commonly used in food and beverage packaging, particularly for drinks, juices, and smoothies

PET is used in almost all single-use bottles, soft drinks, and water-based beverages sold in the United States (polyethylene terephthalate)

They packed salad sauces, peanut butter, cooking oils, mouthwash, shampoo, hand sanitizer, window cleaner, and even tennis balls

Special grades of PET are utilized in food containers and prefabricated metal trays that can be reheated in the oven or microwave

PET is made up of ethylene glycol and terephthalic acid, which are mixed to form polymer chains

Extruded PET spaghetti strands are immediately cooled and chopped into tiny balls

The resin pellets are then heated until they become a molten liquid that can be readily extruded or molded in any shape

PET was originally manufactured in North America in the mid-1940s by DuPont researchers looking for novel synthetic fibers

Later, DuPont dubbed its PET fibers “Dacron” PET, referred to as “polyester” when used to make fibers or textiles, now accounts for more than half of the world’s synthetic fibers

It is referred to as PET or PET resin when used for containers

Researchers discovered a means to stretch a sheet of extruded PET film in two directions in the late 1950s, resulting in PET film, which is now widely utilized in video production, imaging, and packaging

The PET bottle blow molding technique was created in the early 1970s

PET bottles were first registered in 1973

PET is authorized for safe contact with food and drinks by the US Food and Drug Administration (FDA) and worldwide health authorities

PET’s safety in food, beverage, pharmaceutical, and medical applications has been demonstrated repeatedly over the course of more than 30 years of significant study, regulatory approval, testing, and general adoption

PET has no bisphenol A (BPA) or phthalates (a lubricant)

PET is quickly becoming the packaging material of choice for food and drinks because of its unique features

It is a durable and inert substance that, like glass, does not react with food, is resistant to microbial assault, and is not biodegradable

However, PET is extremely lightweight, pleasant, transportable, and indestructible, unlike glass

PET is entirely recyclable and the most extensively recycled plastic in the United States and worldwide

Every year, more than 1

5 billion PET water bottles and containers are recycled in the United States

PET is readily recognizable by the number 1 in the triangle “chasing” symbol, which is commonly seen on the container’s bottom or side

There is no other plastic with code #1

PET may be recycled commercially by thoroughly cleaning and remelting it or chemically dissolving its components to produce new PET resin

PET containers are accepted by almost every metropolitan recycling program in North America and Europe

New PET bottles and cans, carpets, garments, synthetic tape, and rope are products manufactured from recycled PET

Automobile parts, winter coats, sleeping bag fills, building supplies, and protective packing

The current PET recycling rate in the United States is 31%

This ratio is increasing but still trails behind Europe, which has a 52 percent PET recycling rate

Although recycling is the most environmentally beneficial and efficient resource reuse strategy, PET bottles and containers that wind up in the landfill pose a minimal chance of harm or leaching

Because the polymer is inert, it is resistant to microorganism attack and will not disintegrate biologically

PET also consumes a relatively minimum landfill area as it is quickly crushed flat

According to the EPA, PET containers make for less than 1 percent of municipal solid garbage in the United States

PET is a highly effective packaging material

Despite the fact that its main constituents are manufactured from crude oil and natural gas, it has a considerably higher sustainability profile than glass, aluminum, and other container materials

When recycling is adopted, its sustainability grows even more as roughly 40 percent of PET’s energy consumption is related to its “resource energy”

The energy inherent in its raw materials may be recovered and reused through recycling

PET’s tremendous strength concerning its light weight is a crucial contribution to its energy efficiency, allowing more items to be carried in less packaging while needing less fuel for transportation

Continuous improvements in light-weighting technology continue to boost its energy efficiency

PET life cycle studies have frequently proven the environmental benefits of the drug

PET has become one of the world’s most regularly used, versatile, and trustworthy materials in the 60 years after it was initially invented

Name for plastic raw materials

One of the most commonly used plastic products raw materials used widely in the industry has the name Polyethylene terephthalate or PET

The utilization of polyethylene terephthalate (PET) bottles has risen in recent years, and the disposal of PET bottles after use has produced economic and environmental issues

PET bottles may be recycled through the chemical polymerization of PET chains into monomers or other valuable substances

The polymerization pathways may be categorized depending on the chemicals used to dissolve the polyester series, such as glycolysis, methane breakdown, hydrolysis, etc

The decomposition of methane is crucial in the polymerization of low-quality PET bottles

Hydrolysis generates terephthalic acid (TPA) and ethylene glycol (EG), which serve as monomers in TFA-based PET factories for direct manufacturing of PET

The kinetics of PET polymerization is crucial for designing a commercially effective depolymerization method

These choices are designed for PET breakdown and comprise different methanol decomposition and hydrolysis procedures

PET (polyethylene terephthalate) is one of the most regularly used thermoplastics on the globe

Because PET is widely employed in the food and beverage industries, thermoplastics account for the bulk of garbage

For many years, the recycling of PET garbage has been an environmental problem owing to mass production

Because of the carbon emissions associated with pyrolysis-based PET recycling, the use of PET waste in building materials, notably concrete manufacture, is the preferred solution

Alternative approaches, rather than utilizing PET directly in building materials, may be applied

PET Scrap Ductyl Terephthalate (DOTP) is a building material that is oil compatible with concrete raw materials

Consequently, the qualities of DOTP reinforced concrete are crucial in selecting the route of PET waste disposal

Performance studies of DOTP reinforced concrete in the literature will be compared with PET reinforced concrete in this chapter

Plastic pollution is rapidly considered one of the most critical environmental challenges globally

Among the countless polymers, polyethylene terephthalate (PET) plays a key role, and its abundance in the form of garbage is a serious environmental concern

PET contamination is commonly managed using mechanical, thermal, and chemical treatments

However, these procedures are either costly or result in secondary pollutants

As a consequence, for the effective treatment of PET-based plastic garbage, an economical and environmentally sound technology is necessary

With this in mind, one of the most critical techniques to reduce PET contamination is enzymatic treatment or recycling

PET hydrolyses for treating PET waste have been explored in this regard

These enzymes bind to PET and prevent it from breaking down into monomers, resulting in weight reduction

However, various aspects impact this enzymatic activity, particularly PET crystallization, temperature, and pH

PET hydrolysis requires high temperatures, which gives substrate (PET) access to the enzyme

On the other hand, heat-resistant enzymes are essential to act at such high temperatures

Glycosylation, stabilization, and enzyme engineering may enhance heat stability

Furthermore, surfactants and additives such as calcium, magnesium, and hydrophobins (cysteine-rich proteins) have been demonstrated to increase PET enzymatic hydrolysis by improving access to PET polymers

This review presents a high-level overview of the use of enzymes in processing PET waste

This research also reveals the multiple strategies that impact the course of treatment and the various constraints that are enforced

Plastic raw materials for soap production pdf

Is the production of soap made from plastic raw materials for space possible? Some people may get to these subjects in pdf files on the internet

In recent years, the use of polyethylene terephthalate (PET) bottles has risen, and post-consumer disposal of PET bottles has generated economic and environmental difficulties

PET bottles may be recycled by chemically polymerizing PET chains into monomers or compounds of varied value

Depending on the chemicals utilized to dissolve the polyester series, the polymerization pathways may be categorized into the following types: Glycolysis, methanolysis, hydrolysis, and so on

Methane breakdown is crucial in the polymerization of inferior PET bottles

Hydrolysis generates terephthalic acid (TPA) and ethylene glycol (EG), which serve as monomers in TFA-based PET factories for direct manufacturing of PET

The kinetics of PET polymerization is crucial for designing a commercially effective depolymerization method

These choices, which comprise numerous methanol breakdown and hydrolysis processes, are meant for PET decomposition

One of the most widespread thermoplastics in the world is polyethylene terephthalate (PET)

Because PET is widely employed in the food and beverage industries, thermoplastics account for the bulk of garbage

PET scrap recycling has been an environmental challenge for many years due to mass production

Because of the carbon emissions associated with pyrolysis-based PET recycling, the use of PET waste for construction materials, notably concrete manufacture, is the preferred solution

Alternative approaches, rather than utilizing PET directly in building materials, may be applied

PET Scrap Ductyl Terephthalate (DOTP) is an oil-based product compatible with concrete raw materials and visually pleasant

Consequently, the properties of DOTP reinforced concrete are highly significant in selecting the route of PET waste disposal

This chapter will compare the performance of DOTP reinforced concrete to PET reinforced concrete in the literature

Plastic pollution is rapidly considered one of the most critical environmental challenges globally

Polyethylene terephthalate (PET) is a significant plastic, and its excess in the form of rubbish is an essential ecological threat

PET contamination is often managed using mechanical, thermal, and chemical treatments

However, these procedures are either costly or result in secondary pollutants

Consequently, an economical and environmentally suitable method for handling PET-based plastic garbage is necessary

However, one of the most essential techniques to reduce PET contamination is enzymatic treatment or recycling

Hydrolysis of PET has been explored in this context for treating PET waste

These enzymes attach to PET and prevent it from degrading into monomers, which may result in weight loss

Many elements, most notably PET crystallization, temperature, and pH, may impact this enzymatic process

PET hydrolysis demands a high temperature in order for the substrate (PET) to be accessible to the enzyme

On the other hand, heat-resistant enzymes are essential to act at such high temperatures

Glycosylation, stabilization, and enzyme engineering may enhance heat stability

Furthermore, surfactants and additives such as calcium, magnesium, and hydrophobins (proteins high in cysteine) have been shown to improve the enzymatic hydrolysis of PET by increasing the availability of PET polymers

This study presents a brief description of the use of enzymes in the processing of PET waste

This research also underlines the different strategies that impact the course of treatment and the limits that emerge from them

In this article, we had a short overview of plastic raw materials including Polyethylene terephthalate or PET, Polyethylene or PE, Polyvinyl chloride or PVC, Polypropylene or PP, Polystyrene or PS, Polylactic Acid or PLA, Polycarbonate or PC, Acrylic or PMMA, Acetal or Polyoxymethylene (ROM), Nylon or PA, and ABS or Acrylonitrile Butadiene Styrene

We also explained PET and its usage in the industry and construction to some extent

Plastic raw materials produced in our company are among the best in the world

We advise you to test our raw materials once in your manufacturing company if you are a producer or a wholesaler and would become our lifetime customer

Our experts are here for you if you have any questions regarding the quality and other features of our plastic raw materials